The Debris Mapping Tool, DMT, can be fitted to an operators’ production pig or it can be supplied as a standalone unit.

The DMT uses the same electronics module as the PET and gathers the same data set. However, in addition, depending on the nominal pipeline diameter it can accommodate up to 96 debris measurement sensors.

The DMT sensors provide 360° coverage, are in direct contact with the pipewall and are used to accurately measure hard or soft pipewall deposits and or debris. The DMT will identify the thickness, linear location, clock position and the volume of debris deposited along the length of the pipeline.

Available to suit a variety of pipe diameters, the DMT provides pipeline operators with the information they need to verify and optimise pipeline cleaning strategies and programs.

Through innovative assessment and presentation of the DMT data, a pipeline operator can:

- Verify and optimise pipeline cleaning programs

- Remove uncertainty and improve understanding of their pipelines internal condition

- Optimise pipeline operating costs

- Promote and assess likelihood of first run ILI success

- Elimination of ILI failure

- Minimise pig trap operations for launch activities

- Ensure safe, reliable, efficient and verified routine cleaning regimes

- Reduce risk to personnel due to unnecessary exposure to pig trap operations

Periodic use of tools like the DMT form an essential part of P2D’s client specific ‘Pipeline Healthcare’ programmes that integrate seamlessly with an Operator’s flow assurance strategy.

The DMT is available in sizes 10” to 56”, with retro-fitting also available.

Applications

- Quantify the thickness, distribution and potential volume of pipeline debris along the entire length of the pipeline

- Evaluate the efficiency of production cleaning pigging strategies with regard to pig type and run frequency

- Evaluate the performance of standard and or specialised cleaning pigs

- Evaluate the effectiveness of chemical cleaning programs

- Provide a “Go/No Go” indicator before running an ILI tool

- Evaluate the efficiency of pre-inspection cleaning programs, before, during and after implementation

- Develop “intelligent cleaning” programs where routine measurement of actual pipeline conditions can be used to optimise pipeline healthcare strategies

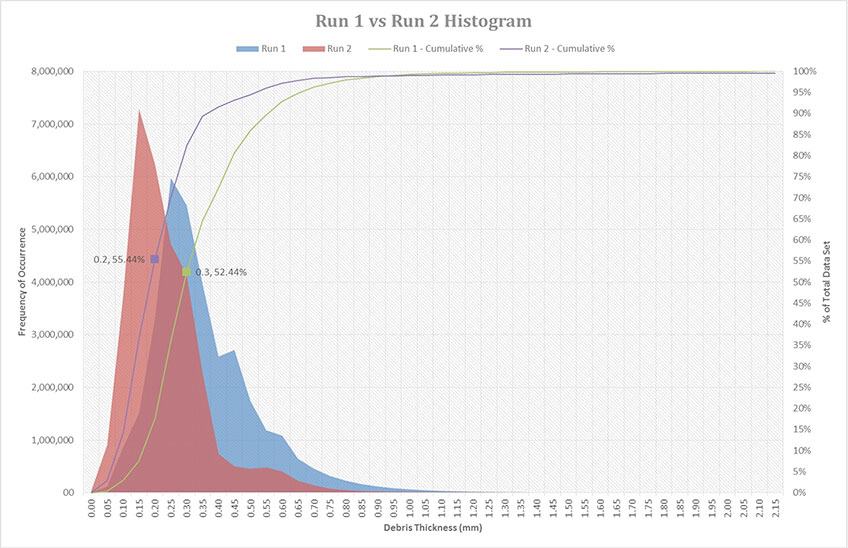

Debris mapping assessment comparison to verify the performance of a cleaning regime and promote first run ILI success

| Operating Pressure | @0-200 Barg |

| Operating Temperature | -5°C to +100°C |

| Flow Rate | 0.5 – 5m/s |

| Battery Life | 6 days |

| Data Storage | 32Gb |

| Front & Rear Pressure | 0-200 Barg |

| Temperature Reading | -10°C to +120°C |

| Tri-Axial Accelerometer | +/- 3g |

| 6 axes IMU | Accels - +/- 5g, Gyros – 300 deg/sec |

| DMT sensors | 8 – 48 |

| DMT sensor measurement range | 0-20mm |

The above can be tailored to suit client requirements.