Available to suit a variety of pipeline diameters and pig types, the fully ATEX certified PET provides pipeline operators with an understanding of the behaviour of pigs whilst negotiating their pipeline system.

The PET can be retrofitted to standard mandrel pigs, foam pigs and flexicast pigs ensuring knowledge of all pig types is attained. The PET is a cost effective solution which, through innovative assessment and presentation of the data.

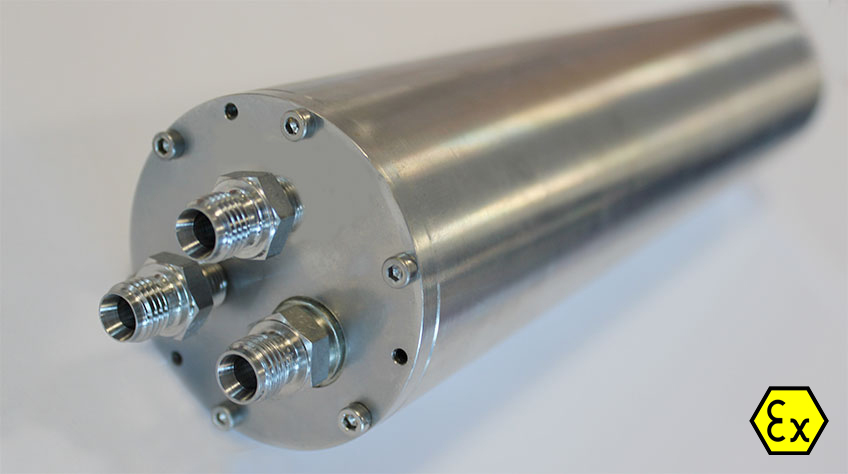

The P2D Pipeline Environment Tool fully ATEX certified data logging module

A pipeline operator can:

- Determine an accurate pressure and temperature profile for the pipeline permitting refinement of deposition and flow assurance modelling

- Remove uncertainty and improve understanding of their pipelines internal condition

- Identify and monitor upheaval buckles, bore reductions and pin point their location (gauge plate can be added)

- Monitor their pipeline environment for changes e.g. increasing pig DP suggesting reducing pipe bore

- Monitor pig performance ensuring cleaning remains effective e.g. reducing pig DP demonstrating poorer cleaning performance

- Mitigate ILI risk by preforming an intelligent reconnaissance pig run pre ILI scope

The P2D PET’s versatile sensor and electronics framework allows bespoke configuration to match the specific requirements of the project.

The PET can be run as part of a pigging programme that monitors the pipeline conditions at different times, events and flow rates.

Applications:

- Low cost pipeline condition monitoring

- Optimise pipeline cleaning programs

- Semi-intelligent gauging

- Pipeline pressure and temperature profiles

- Easily adapted to suit a range of associated client requirements

- Monitor pig cleaning effectiveness and efficiency

- Evaluate pipeline parameters

- Evaluate new cleaning pig designs during testing and operations

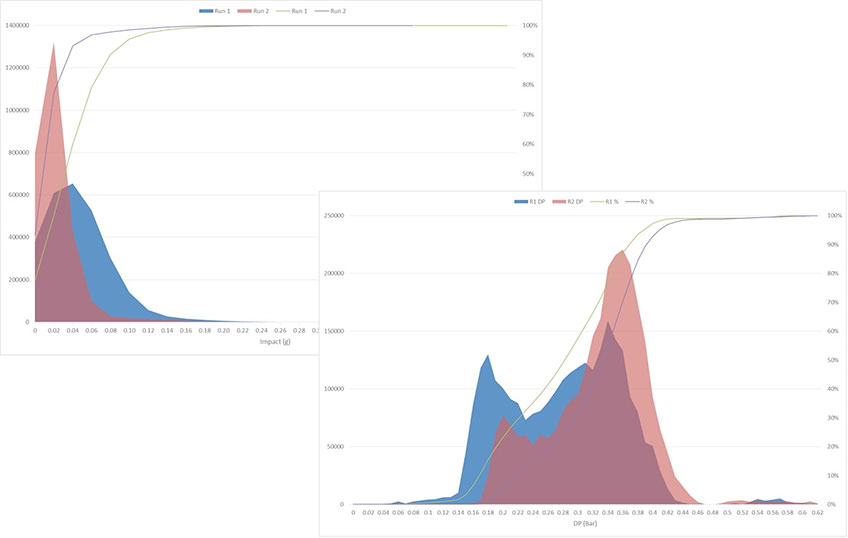

PET Data Examples

Pig performance assessment comparison to verify the changes in pig ride characteristics created by a change in pipeline condition

| Operating Pressure | 0-200 Barg |

| Operating Temperature | -5°C to +100°C |

| Pig Velocity | 0.1 to 10 m/s |

| Battery Life | 11 days |

| Data Storage | 8Gb |

| Front & Rear Pressure | 0-200 Barg |

| Temperature Measurement Range | -10°C to +120°C |

| Odometers | 2 maximum |

| Tri-Axial Accelerometer | +/- 3g |

The above can be tailored to suit client requirements.